25 Hp Electric Motor Calculator

Understanding the 25hp Electric Motor

The 25hp electric motor is a powerful machinery component widely used in various industrial and commercial applications. It converts electrical energy into mechanical energy, providing consistent and reliable performance for tasks like driving pumps, fans, and compressors. Understanding how a 25hp electric motor operates and its components is essential for anyone looking to utilize or maintain these motors effectively.

How Does a 25hp Electric Motor Work?

The 25hp electric motor works based on the principles of electromagnetism. When an electric current passes through coils of wire within the motor, it generates a magnetic field. This magnetic field interacts with the motor’s stator and rotor, resulting in rotational motion. The key components include:

- Stator: The stationary part of the motor, housing the windings.

- Rotor: The rotating part that transforms electrical energy into mechanical torque.

- Windings: Coils of wire that create magnetic fields when energized.

- Bearings: Allow smooth rotation of the rotor within the stator.

Benefits of Using a 25hp Electric Motor

There are several advantages to using a 25hp electric motor, including:

- Energy Efficiency: Electric motors are generally more efficient and cost-effective over time than their fossil fuel counterparts.

- Low Maintenance: They require less maintenance due to fewer moving parts compared to combustion engines.

- Environmentally Friendly: Operating on electricity reduces harmful emissions.

Common Mistakes When Using the 25hp Electric Motor

When working with a 25hp electric motor, avoid these common pitfalls:

- Improper Sizing: Always ensure that the motor is appropriately sized for the application requirements.

- Neglecting Maintenance: Regular checks can prevent issues down the line.

10 Key Facts About 25hp Electric Motor

- How does 25hp electric motor work? It converts electrical energy into mechanical energy using electromagnetic principles.

- Can you easily install a 25hp electric motor? Yes, especially if you have basic electrical knowledge and follow the manufacturer’s guidelines.

- What applications use a 25hp electric motor? Common applications include manufacturing, HVAC systems, and water pumping.

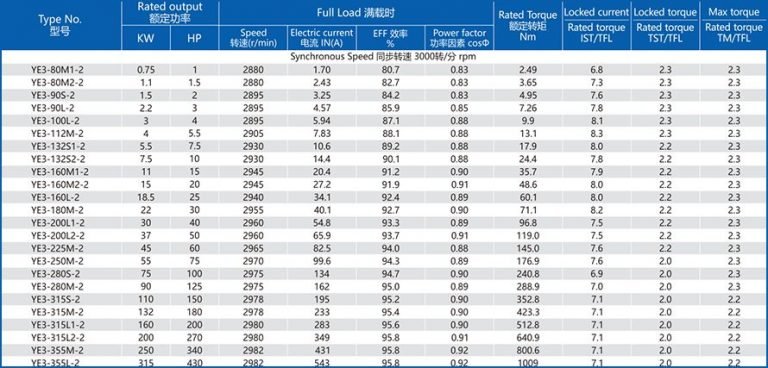

- Does the efficiency vary in a 25hp electric motor? Yes, efficiency can vary based on load conditions and motor design.

- How to maintain a 25hp electric motor? Regular cleaning, lubrication, and ensuring connections are tight can prolong its lifespan.

- What voltage options are available for the 25hp electric motor? They typically operate on 230V, 460V, or 575V systems.

- Can you upgrade to a more efficient model? Yes, exploring newer models may offer improved efficiencies and technologies.

- What is the typical lifespan of a 25hp electric motor? With proper maintenance, they can last 15-20 years or longer.

- Are there any risks with a 25hp electric motor? Risks include electrical hazards and overheating if not installed correctly.

- Can you use a variable frequency drive with it? Yes, a variable frequency drive (VFD) can improve motor control and energy consumption.

Wow, a 25hp electric motor? That’s pretty powerful! 🚀 How does it compare to gas engines? I’ve been thinking about switching my tools over to electric. Anyone have experience with that?

Ehhh, I wonder about the longevity of these things. Heard mixed reviews about electric motors. Do they last as long as traditional ones?