Motor Conductor Sizing Calculator

Understanding Motor Conductor Sizing

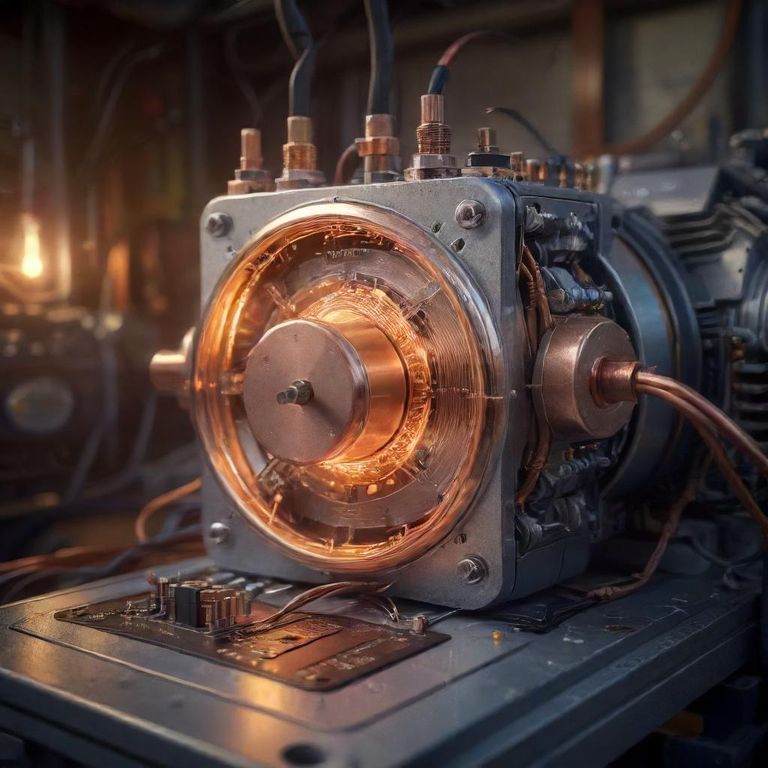

Motor conductor sizing is an essential aspect of electrical engineering that ensures safety, efficiency, and performance in electrical installations. Properly sized conductors minimize energy loss and reduce the risk of overheating, making it crucial for both residential and industrial applications.

Key Considerations for Sizing Conductors

When undertaking motor conductor sizing, consider the following factors:

- Voltage drop: Ensure the conductors maintain acceptable voltage levels.

- Current carrying capacity: Select conductors that can handle the load without excessive heat generation.

- Ambient temperature: Account for higher temperatures which can affect conductor performance.

Basic Formula for Motor Conductor Sizing

The basic formula for calculating the required conductor size is:

Ampacity = (Motor Full Load Current) * (Safety Factor)

This formula helps determine the minimum ampacity of conductors required for specific motor applications.

Tips to Motor Conductor Sizing

Here are some effective tips:

- Consult the National Electrical Code (NEC) for guidelines on conductor sizing.

- Utilize online calculators to streamline the sizing process.

- Regularly review existing installations to ensure compliance with updated standards.

10 Key Facts About Motor Conductor Sizing

- What is the purpose of motor conductor sizing? It ensures electrical safety and efficiency.

- How does motor conductor sizing work? It calculates appropriate wire sizes based on load requirements.

- Can you easily motor conductor sizing? Yes, especially if you use reliable calculators or tools.

- Why is thermal capacity important? It prevents overheating and reduces fire risks.

- Do installation conditions affect sizing? Absolutely, ambient temperature and installation method play critical roles.

- How often should conductor sizing be reviewed? Regular reviews, especially after upgrades, are essential.

- Is there such a thing as oversized conductors? Yes, which can lead to increased material costs and difficulty in handling.

- Can different materials affect sizing? Yes, copper and aluminum have different ampacity ratings that can impact sizing.

- What’s a common mistake in motor conductor sizing? Ignoring voltage drop can lead to inadequate performance.

- Are there alternatives to traditional sizing methods? Yes, new technologies offer advanced sizing tools and software solutions.

Motor conductor sizing can be a total headache! 😅 I remember when I had to figure it out for a project, and honestly, it took me forever. Anyone got tips to make it easier?

Honestly, I find sizing conductors a bit tedious, but super important! Didn’t realize how crucial it was until I had some overheating issues. Anyone else been there?